Dimensional Stability in Plastics: Key Factors and Materials

If a material is dimensionally stable, it keeps its shape and exact dimensions throughout the manufacturing process and during use, […]

Nylatron® vs. Nylon MDS

Depending on the application, nylon MDS or Nylatron® may be an ideal material. Learn more about their chemical, physical, and […]

What Are Nylon Spacers and What Are They Used For?

Nylon spacers are a critical yet often overlooked component across diverse industries. Used to lengthen the space between connected parts, […]

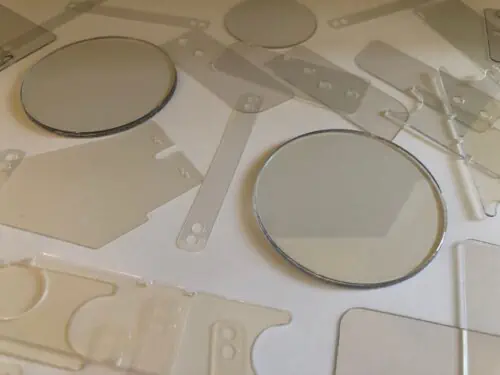

What Is Lexan/Polycarbonate, and What Are Its Applications?

What Is Lexan Plastic? Lexan is a brand name for polycarbonate, a plastic popular for its flexibility and durability. The […]

What Is Nylatron®?

Since 1927, New Process Fibre has been a leading provider of high-quality commercial and industrial components. Our versatile facility allows […]

The Differences Between Nylon 6, Nylon 6/6, and Nylon MDS

When it comes to producing nonmetallic stamped components, manufacturers have several material options to choose from. Nylon is often a […]

Trends in Reshoring

As a family business, we place a special emphasis on providing clients with fully in-house solutions. Since 1927, New Process […]

When Nylon Washers Are Your Best Choice

Nylon washers are one of the most frequently used types of hardware for industrial design purposes. They’re critical components of […]

An Overview of New Process Fibre

For generations, New Process Fibre’s family-owned business has strived to provide ever-improving products and maximum quality while maintaining cost-effectiveness. As […]

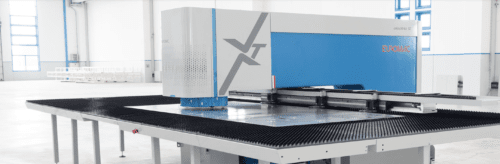

Working with New Process Fibre: Tooling & Machinery

As an ISO 9001:2015 registered manufacturer, New Process Fibre offers superior quality tool and die manufacturing and nonmetallic stamping services […]