New Process Fibre is unique in several ways. We believe that our ability to provide OEMs with cost-effective and innovative stamping solutions for nonmetallic parts is second-to-none. Moreover, our huge inventory of die-sets gives us the ability to turn around both large and small runs very quickly. That is why we are viewed as industry leaders in the fabrication of nylon washers.

One of the most commonly used hardware products is a washer, which is a thin disk typically used for distributing the load of a threaded fastener such as a screw, bolt, or nut. Washers are highly useful as they not only prevent corrosion, but they can be designed for a large range of applications. Furthermore, they come in a wide variety of materials, including aluminum, bronze, steel, copper, and nylon.

Nylon is a synthetic material that can be melted into various shapes and fibers. Known for its versatility, nylon is a popular option for its machinability, chemical and abrasion resistance, and flexibility. It comes in a number of types, including Nylon 6, Nylon 6/6, Nylon MDS, and Nylatron®. Nylon is also a non-flammable material that is non-toxic as well as weather resistant. Because of these properties, nylon is often the preferred material for washers.

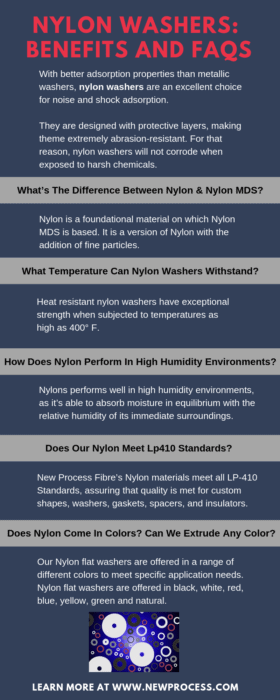

Nylon washers are particularly useful as a lightweight, durable alternative to standard metallic washers. Offering excellent insulation and strong adsorption properties, nylon washers are ideal for chemical and electrical applications. These washers are valuable for their ability to maintain their appearance and performance over a prolonged period of time.

Nylon washers evenly distribute pressure from a nut or bolt across the surface to which it’s fastened. Washers also protect the surface from damage by separating it from the fastener. In addition, washers help mitigate the threat of vibrations or other environmental factors that may loosen fasteners over time.

Industry applications for Nylon washers

Industry Applications for Nylon Washers

Nylon — perhaps most well known as a common fabric in clothing — is actually a strong and highly versatile material that is used in all sorts of demanding industry applications. For instance, the medical industry uses Nylon to make medical instruments; the plumbing industry uses Nylon to provide trustworthy seals; and the fire safety industry uses Nylon in sprinkler systems due to the material’s reliability.

At New Process, we use Nylon to make flat washers with exceptional performance characteristics. We use four different types of Nylon: Nylon 6, Nylon 6/6, Nylon MDS, and Nylatron®.

Nylon washers have a centrally located hole through which the fastener enters to join with the object. Manufacturers produce washers from several kinds of material, including

Although most applications use metallic washers, nylon washers are growing in popularity as a light-weight alternative. Using nylon washers comes with several advantages, including:

- Excellent insulation properties

- Fireproof properties

- Non-toxicity

- Resistance to friction

- Resistance to corrosion

- Light weight

- Cost effectiveness

Here are some quick facts to give you a better idea of our machining capacity:

- 75 punch presses with various tonnage ratings — 14 of which are high-speed presses that operate at up to 400 strokes per minute. Our machines process both strip stock and coil stock,

- More than 10,000 washer dies in stock

- A huge inventory of materials, including several types of Nylon — in various colors.

MOST OF OUR CLIENTS THAT USE CUSTOM NYLON WASHERS FALL INTO ONE OF THE FOLLOWING FIVE INDUSTRIES:

An overview of our very own New Process Fibre nylon washers.

Nylon Washers versus Teflon Washers

Nylon washers and Teflon washers are both made of versatile synthetic polymers that offer higher mechanical strength thresholds and better resistance to friction than traditional metallic substances. Industries across the board use both nylon and Teflon washers in many applications.

However, several noteworthy differences exist between nylon and Teflon. Each material is made using different chemical processes. Nylon forms when an amide reacts with dicarboxylic acid, and Teflon results from the polymerization of tetrafluoroethylene.

This means that nylon and Teflon each have specific physical and chemical properties. For example, nylon is hydrophilic (meaning it tends to mix with water), whereas Teflon is hydrophobic, or water repellent. Therefore, Teflon is a better choice of material when building machinery that requires higher-than-average amounts of lubrication.

Other differences include:

- Melting points: Teflon has a higher melting point

- Electrical conduction: Nylon conducts electricity better

- Chemical reactivity: Teflon reacts less with chemicals

Sourcing Custom Nylon Washers: Stamped Versus Molded

Manufacturers typically use injection molding to build nylon washers. This forms nylon into the desired shape by injecting molten polymers into molds.

However, over the years, nonmetallic stamping has emerged as a popular and cost-effective alternative to injection molding when creating washers. Nonmetallic stamping comes with several benefits:

Accuracy

For most production requirements, nylon stamping (also known as punching) accurately mass produces identical parts at relatively high speeds.

Uniformity

Injecting molten material in molds often leads to the formation of bubbles or other irregularities that affect the production run’s uniformity. In contrast, nonmetallic stamping creates uniform products with little or no visible abnormalities. This is due in part to how the stamping process can shape an entire set of “blank” materials in just one operation.

Faster Turnaround Times

While the output levels of high-speed stamping equipment may vary, it’s possible to attain punching speeds of up to 400 strokes per minute via nylon stamping. Nonmetallic stamping presses can produce as many as 200,000 nylon washers every day, whereas injection molding can only create approximately 25,000 parts per day.

Cost-Effectiveness

Injection molding may require new molds for each part. However, manufacturers can simply adjust their nonmetallic punch presses to fill the desired order for the customer. This keeps tooling costs down and fills higher order volumes over time. All these factors contribute to increased cost effectiveness for nonmetallic stamping as opposed to injection molding.

Benefits of Custom Plastic Nylon Washers Over Metal Washers

Nylon offers many benefits that metal materials cannot match. Two of these benefits include:

- Nontoxicity: Although metallic substances may release corrosive and toxic byproducts over time, nylon is an inherently nontoxic material. For this reason, many producers use nylon washers in food processing equipment.

- High-cost efficiency: Nylon washers can be strong and durable, allowing them to resist impacts better than metallic washers. Because of this, nylon derivatives such as nylon MDS are strong candidates for use in machinery components.

Benefits of Custom Black Nylon Washers in the Automotive Industry

In automotive applications, black nylon washers offer a popular alternative to metal-based washers. They provide several advantages:

- Nylon washers weigh less than other washer types while preserving their ability to be tough and flexible. This boosts your vehicle’s fuel efficiency and extends its life span.

- Black nylon washers resist harmful chemicals, meaning that they won’t weaken or corrode from contact with petroleum-based substances or engine oil.

- These washers are also versatile, allowing manufacturers to use them in highly specialized automotive applications.

Using PTFE and Nylon 6 in Plumbing Applications

Polytetrafluoroethylene (PTFE) and Nylon 6 are two nonmetallic materials that provide long-lasting and less expensive alternatives to

standard metal washers in plumbing applications.

PTFE is totally impermeable to water, water-containing substances, oil, and oil-containing substances. For this reason, it’s an ideal choice for plumbing applications, and manufacturers of plumber’s tape (also called thread seal tape) use this material in their products. PTFE also provides good thermal and electrical insulation, and it has a low coefficient of friction.

The impact strength and energy absorption attributes of Nylon 6 increase with moisture absorption. However, exposure to moisture may also decrease its stiffness and tensile strength. However, when plumbers properly account for these negative effects, Nylon 6 washers benefit applications including showerheads and faucets.

Custom Plastic Nylon Washer Solutions From New Process Fibre

Since 1927, New Process Fibre has provided innovative fiber solutions to our clients. With state-of-the-art tooling and a wealth of expertise, we consistently exceed customer expectations on a wide variety of projects.

Contact us today at New Process Fibre to learn more about how using our nylon washers will benefit your applications.

Custom Nylon Washer Options from New Process Fibre

Nylon materials from New Process Fibre meet all LP-410 Standards, ensuring that quality is met for custom shapes, washers, gaskets, spacers, and insulators. We offer nylon flat washers in a range of different colors to meet specific application needs. Colors we have available include black, white, red, yellow, green, blue, and natural. Request a quote today for more information on our nylon washers, or access our Nylon Washers catalog here.