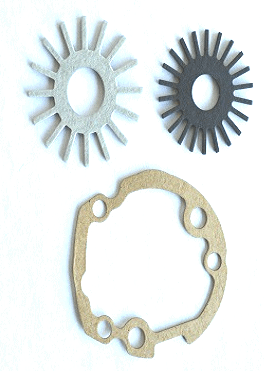

Power Tools

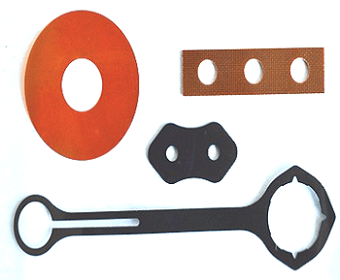

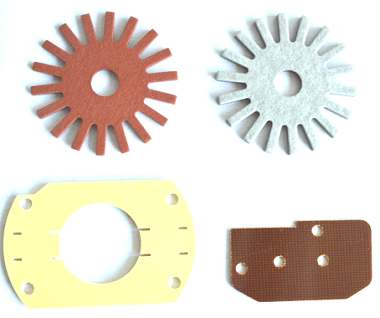

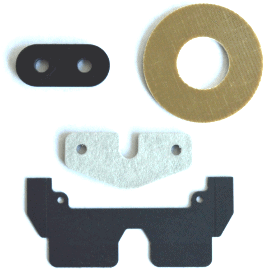

Precise, repeatable, and cost-effective custom gaskets and washers provide valuable protection for electronic power tools by maximizing performance and longevity while shielding the units from fluid and debris. New Process Fibre non-metallic custom gaskets and washers resist water, oil, corrosion, and heat while maintaining an extremely low coefficient of friction. Power tools with New Process custom parts work at peak performance levels in the most challenging industrial conditions.

Some of these custom parts include:

- Self lubricating nylon MDS washers

- Custom end laminations

- Euro blade

- Gaskets

- And much more!

Furniture

Washers distribute the pressure of bolts to prevent material damage and excessive wear; the components also hold screws and bolts in place. Non-metallic discs and custom parts help furniture resist vibration, corrosion, thermal expansion and contraction, and threading damage.

These furniture products may include:

- Desks

- Tables

- Chairs

- Sofas

- Recliners

- And much more!

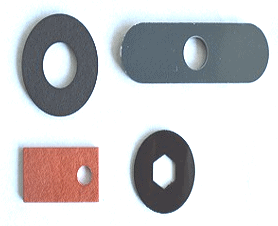

Fasteners

For maximum accuracy and endurance, custom fasteners must be produced with uniform quality and precision. We are ISO 9001-2015 certified, stamping custom-designed military fasteners from premium non-metallic materials. We can produce nearly any custom shape, and our stamping equipment works at tight tolerances to meet or exceed all Mil-Spec standards.

- Self retaining Washers

- Flat washers

- Shoulder washers

- Spacers

- Shims

- And much more!

Medical

With exceptional strength and temperature resistance, our non-metallic nylon parts are the most suitable for today’s medical equipment and devices. Nylon is a lightweight and non corrosive material, that helps components remain sterile and free from other health risk factors, making it a suitable choice.

- Face shields

- Respirator components

- Table components

- And much more!

Farm and Garden

The usage of plastics are increasing in this industry, particularly in agricultural equipment. This equipment includes tractors, combines, plows and balers. We have even seen large companies like John Deere and International Harvester both begin to transition away from sheet metal and into plastics. As more non-metallic materials are being used, we are beginning to see just how versatile and durable plastics can be compared to their non-metallic counterparts.There are some obvious advantages to these changes as non-metallic parts tend to fare better in harsh or moist conditions, but we are seeing this transition mainly due to the following:

- Reduce weight, costs, complexity of machinery

- Additionally, reducing farm operations not related to crop picking

- Insulators

- And much more!

Marine

Having a corrosion resistant material is an absolute must in marine environments, making Nylon a preferred material for components in this situation. Our marine industry partners choose nylon because — aside from its durability — it does not require lubrication or coating of any kind. Nylon is typically found in the following marine applications:

- Stern tubes

- Winches

- Rudder stocks

- Capstans

- Sheaves

- And much more!

Aerospace and Military

Precision, accuracy, and repeatability are three crucial characteristics in aerospace and military engineering. Nylon is ideal for these demanding industries because of its high chemical resistance, durability, abrasion resistance, and non-flammability. Nylon 6/6 and Nylatron® are especially common in these industries because of their increased heat resistance and lubricity.

Our custom, non-metallic parts provide excellent performance in demanding conditions, offering resistance to oil, water, chemicals, and wide temperature swings.

- Fasteners

- Airframes

- Avionics

- Ammunition

- Parachutes

- Shoulder boards

- Hydraulics

- Flight control systems

- Insulators

- Night vision glasses

- And much more!

Government

In the food and beverage industry, plastic components must be used in order to keep foods sterile and for consumer safety, these parts then need to be approved by the FDA and USDA before they hit the market.

- Identification tags

- Postal sorting machines

- Police vehicle tags

- Insulators

- And much more!

Sporting Goods/Fitness Equipment

As we have developed better technology for sports, the use of non-metallic materials has played a large role in increasing durability of the equipment, but more importantly reducing the weight of it:

- Bicycles have gotten about 5lbs lighter in recent years due to advancements in materials for the equipment

- Playgrounds have also been utilizing non-metallic components in order to avoid corrosion over the years

- Spacers

- Bow and arrow components

- And much more!

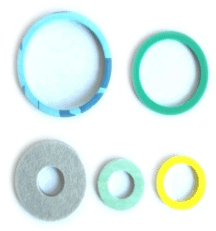

HVAC

HVAC systems in industrial settings can undergo significant vibrations due to air current and moving system parts. Teflon PTFE washers are a great material to use in this scenario and will help mitigate the vibrations that are produced, preventing wear and tear on the machinery while simultaniously extending its lifetime.

- Compressor seals

- Teflon washers

- Connectors

- End laminations

- And much more!

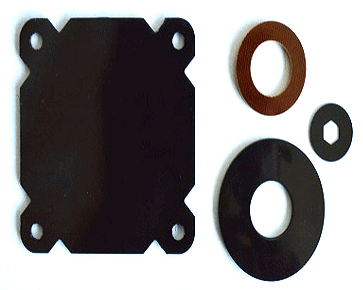

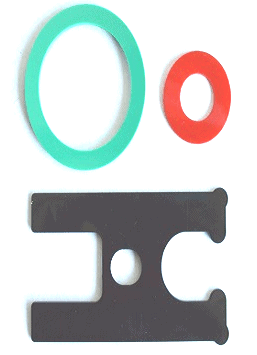

Plumbing

Washers are ubiquitous in plumbing applications

such as fixtures and sprinkler systems. While

plumbers heavily use metal washers, non-metal

alternatives offer the same protection and

performance at lower costs.

Materials such as Nylon 6 and Teflon™ PTFE provide

excellent resistance to water, wear, corrosion, and

large temperature changes. Non-metallic washers

and custom parts can also be constructed with

other fibers to improve their mechanical properties

whenever necessary.

- Faucets

- Drains

- Shower heads

- Shower hoses

- Toilets

- Plungers

- Seal and Washer for PBC

- And much more!

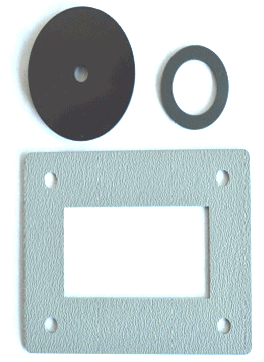

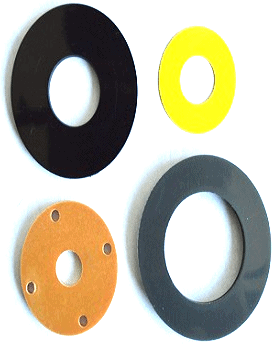

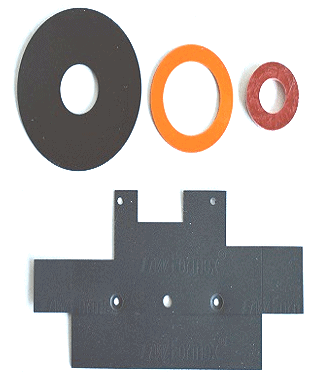

Electronics

Our custom-stamped gaskets and insulators lead the industry in electrical protection. Teflon™ PTFE, Formax & Vulcanized Fibre, and other insulators meet or exceed the insulating properties required for electronics and electrical applications, as well as offer exceptional chemical resistance, strength, stability, and resistance to vibration in virtually any operating temperature.

We produce custom insulation for the following applications and more:

- Electrical insulation components

- Transformers

- Heat sealing

- Motor and switch insulation

- Insulators

- Electrical switch components

- Lighting components

- Terminal boards

- Circuit breaker parts

- And much more!

Consumer and Kitchen Appliances

Custom stamped discs, spacers, tags, and end laminations are heavily utilized for consumer and kitchen appliances. New Process manufactures parts featuring excellent thermal insulation and chemical resistance, allowing them to withstand corrosive materials, electricity, and temperatures up to 600°F. With our custom parts, appliances achieve increased strength and longevity, including resistance to water and oil as well as internal protection against food particles

Our parts serve applications such as:

- Food processors and Blenders

- Freezers

- Furnaces

- Vacuum cleaner canisters

- Air purifiers

- Merchandise tags

- Table leg anti-wobble

- Shim

- Household appliances

- Refrigerator door

- Spacers

- A/C units

- Dishwashers

- Washer and dryers

- And much more!

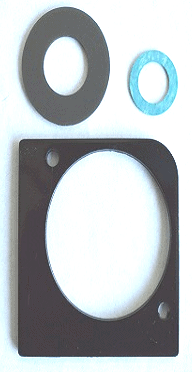

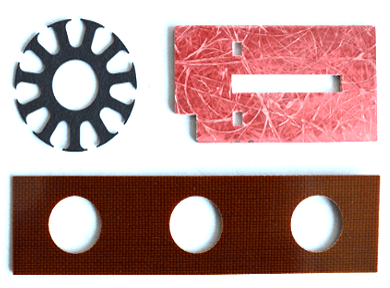

Automotive

Use of non-metal parts for automotive applications is rapidly increasing, including the utilization of high precision custom gaskets, end laminations for motor components, and versatile washers. Automotive parts must endure difficult conditions and meet stringent quality standards; our parts are available in oil- and water-resistant materials to prevent corrosion and withstand temperature changes in the toughest environments.

Specific applications include:

- Engine compartments stator, armature, and rotor components

- Gasoline motor

- Exhaust

- Fenders

- Airbag systems

- Brake systems

- And much more!

We are proude to continue serving clients with the same dedication and quality our name has come to represent over the past decades - with customers representing industries from every sector.

More Resources