New Process Fibre is an industry-leading, precision tool and die maker, offering a full range of premium quality manufacturing services under one roof. Our state-of-the-art, ISO 9001:2015 registered manufacturing facility maintains the highest standards for quality non-metallic stamping processes, catered explicitly to diverse tooling requirements. By using the latest technology, we not only conform to the most stringent specifications and tolerances, but we do so with a reduction in overall cycle time.

Businesses frequently use the terms tool and die together. There are differences between the two, although they are often used interchangeably. They are both used to form a product from different types of materials. However, while a die is a tool, not all tools are dies.

Request a custom quoteWhat Is Custom Tooling and Die Making?

A tool can be virtually anything that transforms a material into a product, like a cutting blade or drill. Tools can form, cut, mold, or support materials. Dies are a type of pre-shaped tool used with a press to form various materials like metal, plastics, or fiber. The press applies force that pushes the plastic, metal, or composite into the die’s cavity. The result is a product that takes on the size and shape of the die.

Custom tool and die making is the manufacture of plastic molds, stamping dies, jigs, and fixtures to mass produce solid objects. They perform functions like closed die forging, extrusion, and blanking. Manufacturers typically classify dies as simple, compound, or progressive.

What Are the Types of Dies We Make?

At New Process Fibre, we produce both compound and progressive dies, but we aren’t limited only to these. Our extensive capabilities also allow us to create custom dies to fit your needs.

Compound tools achieve a number of cutting and forming actions at once. An example is a washer die that forms the shape of the washer and punches a hole through it at the same time, known as shearing and blanking. These types of tools are highly efficient over time and are less expensive than progressive dies.

Progressive dies perform multiple operations sequentially instead of simultaneously. The actions occur at different stations. As the press moves up and down, the feeding mechanism moves the material into the die. The process results in a finished product.

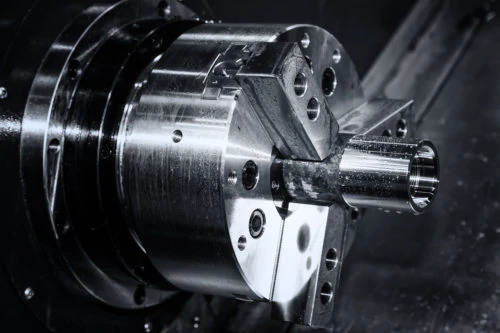

New Process Fibre’s State of the Art Tooling

NPF’s state-of-the-art tooling allows us to accommodate a wide variety of designs and features to suit our customers’ diverse needs. We have a massive material inventory, over 75 conventional and high-speed punch presses, and over 10,000 compound washer dies. Our highly experienced team can create custom tooling for your non-metallic stamped parts.

Our custom die cutter and non-metallic stamping services include:

- CAD/CAM and wire EDM capabilities

- Compound and progressive dies

- Custom die creation

- Economical and critical tolerance tooling applications

- Free maintenance for the life of your program for your tool part design with a partial tooling charge

- Multi-cavity tools enable savings on material costs and improve throughput

NPF is committed to continuous improvement. As part of our ongoing quality assurance procedures, we continuously review and update our systems and processes to ensure we’re meeting the highest quality and customer service standards.

Work With New Process Fibre for Precise Tool and Die Creation

Since 1927, New Process Fibre has been committed to improving manufacturing processes. We are proud to provide non-metallic stamping solutions across a range of industries. With our state-of-the-art tooling and superlative quality processes, we produce a variety of compound, progressive, and custom tool and die solutions under one roof making us an industry leading tool and die maker. For more information, contact us today.