Delrin®️ Washers: What Are They, and How Can They Be Used?

Delrin®️ is a type of polyoxymethylene (POM) originally created by DuPont™. It is a high-performance acetal homopolymer resin known for its high dimensional stability, stiffness, and durability. This thermoplastic has excellent chemical, mechanical, and physical properties suitable for various applications. It can function in extreme temperatures, maintaining its toughness from -50 °C to 90 °C. The material’s characteristics are ideal for heavy loads and high-impact applications, including vehicle components, pump parts, bearings, and gears. Delrin®️ washers are a good choice for demanding applications because of the harsh conditions washers encounter.

Learn more about Delrin®️, its applications, and whether it’s the right material for your washers.

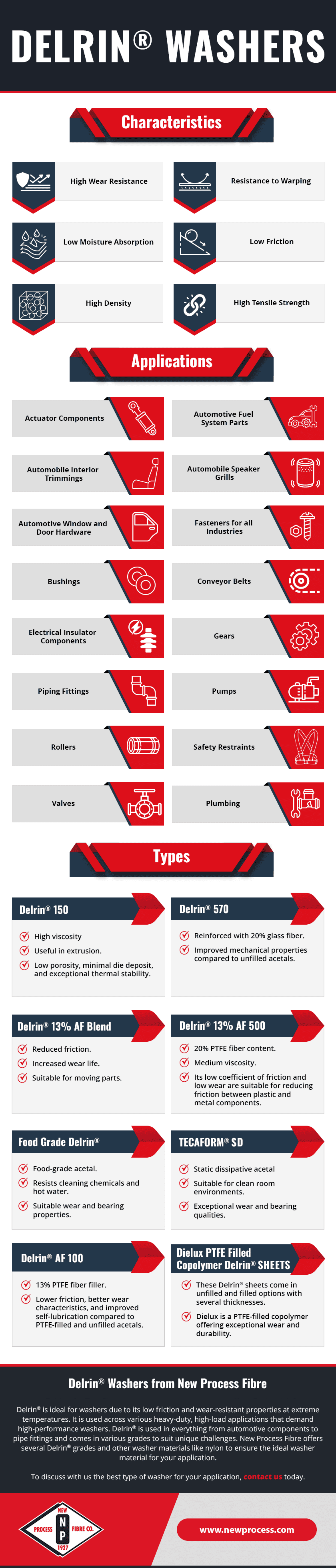

Characteristics of Delrin®️

Delrin®️ provides high wear resistance, resistance to warping, low moisture absorption, low friction, high density, and high tensile strength, making it a suitable replacement for metal components. It is also resistant to chemicals like solvents, hydrocarbons, and neutral chemicals.

Are Delrin®️ Plastic Washers the Best Option for You?

When you order Delrin®️ washers from New Process Fibre, you get our custom manufacturing capabilities and consultative services with fast turnaround times. We can custom-manufacture Delrin®️ shims, plastic washers, and spacers that we can deliver quickly in any volume. We also have many other material options, including PTFE, nylon MDS, nylon 6/6, nylon 6, and polypropylene flat washers. New Process Fibre can produce almost any non-metallic washer material for your needs.

Applications of Delrin®️

What is Delrin®️ used for in commercial and industrial applications? Delrin®️ is available in many different grades to accommodate a wide range of unique applications, including those with exposure to harsh environmental conditions. The petrochemical, food processing, electronics, electrical, and automotive industries rely on Delrin®️ sheets, tubes, rods, washers, and more. Here’s an overview of applications where Delrin®️ is commonly used:

- Actuator components

- Automotive fuel system parts

- Automobile interior trimmings

- Automobile speaker grilles

- Automotive window and door hardware

- Fasteners for all industries

- Bushings

- Conveyor belts

- Electrical insulator components

- Gears

- Piping fittings

- Pumps

- Rollers

- Safety restraints

- Valves

- And much more

Types of Delrin®️

At New Process Fibre, we offer several grades of Delrin®️ to create the ideal washer for any application:

- Delrin®️ 150: This grade’s high viscosity makes it useful in extrusion. It also features low porosity, minimal die deposit, and exceptional thermal stability.

- Delrin®️ 570: This is reinforced with 20% glass fiber to offer improved mechanical properties compared to unfilled acetals.

- Delrin®️ AF 100: A homopolymer acetal with a 13% PTFE fiber filler, resulting in lower friction, better wear characteristics, and improved self-lubrication compared to PTFE-filled and unfilled acetals.

- Delrin®️ 13% AF Blend: A thermoplastic with reduced friction and increased wear life suitable for moving parts. It is made up of uniformly dispersed PTFE fibers in the acetal resin.

- Delrin®️ AF 500: An acetal homopolymer resin with medium viscosity and a 20% PTFE fiber content. Its low coefficient of friction and low wear are suitable for reducing friction between plastic and metal components.

- Food Grade Delrin®️: Also known as TECAFORM®️ FG Blue, this is a food-grade acetal with a blue color. It resists cleaning chemicals and hot water and offers suitable wear and bearing properties.

- TECAFORM®️ SD: A static dissipative acetal containing no carbon powders or fibers, TECAFORM®️ SD is suitable for clean room environments. It has exceptional wear and bearing qualities with a surface resistivity of 109 to 1011 ohms per square. It is best for components subject to fluid flow and frictional static charges.

- Dielux PTFE Filled Copolymer Delrin®️ Sheets: These Delrin®️ sheets come in unfilled and filled options with several thicknesses. Dielux is a PTFE-filled copolymer offering exceptional wear and durability.

Delrin®️ Washers From New Process Fibre

Delrin®️ is ideal for washers due to its low friction and wear-resistant properties at extreme temperatures. It is used across various heavy-duty, high-load applications that demand high-performance washers. Delrin®️ is used in everything from automotive components to pipe fittings and comes in various grades to suit unique challenges. New Process Fibre offers several Delrin®️ grades and other washer materials like nylon to ensure the ideal washer material for your application.

New Process Fibre has been delivering innovative services and products since 1927. We offer a diverse selection of materials—including acetal, nylon, vulcanized fiber, and Delrin®️—so that you can find the ideal non-metallic washer solution for your application. If you already know what products you need, browse our online product catalog. To discuss with us the best type of washer for your application, contact us today.