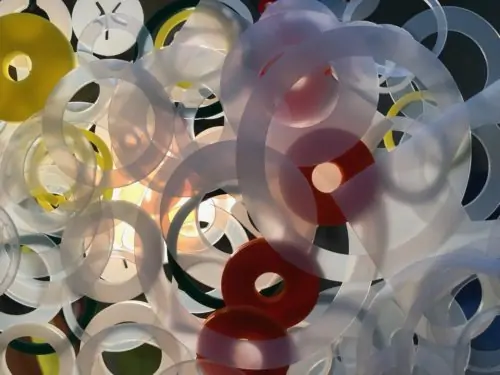

A washer is a flat ring placed between a nut and a bolt on a joining surface to seal a joint or create space. Washers are manufactured in a variety of materials, including metal, rubber, and plastic, depending on their intended use.

Polyethylene is a popular thermoplastic used to manufacture plastic washers, due to its easy formability, low cost, and physical resilience. Polyethylene washers are valued for their sealing ability and electrical insulation properties. There are two types of polyethylene used to create washers: high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Each has unique properties that make them useful for a range of industries and applications.

LDPE vs. HDPE Washers

Although both types of washers are composed of polyethylene, each material has a different fundamental molecular organization. LDPE and HDPE are both derived from ethylene in petroleum, but are manufactured using slightly different methods. Due to variations in manufacturing techniques, LDPE molecules exist in an amorphous structure without organization, while the structure of HDPE is partially or completely crystalline. This divergence gives LDPE and HDPE noticeably different physical characteristics.

Although both types of washers are composed of polyethylene, each material has a different fundamental molecular organization. LDPE and HDPE are both derived from ethylene in petroleum, but are manufactured using slightly different methods. Due to variations in manufacturing techniques, LDPE molecules exist in an amorphous structure without organization, while the structure of HDPE is partially or completely crystalline. This divergence gives LDPE and HDPE noticeably different physical characteristics.

Due to its lack of structure, LDPE is less dense than HDPE. HDPE’s higher density is due to a stronger attraction between the polymer chains that make up the material, whereas LDPE’s polymers are branched. LDPE’s lower density makes it more flexible and elastic, while HDPE’s crystalline structure makes it hard and somewhat brittle. HDPE has the advantage of being stronger than LDPE, but LDPE’s flexibility makes it more malleable and less likely to crack.

Depending on the applications for which the washers are intended, each material has its own particular strengths and weaknesses.

Industry Applications for LDPE & HDPE Washers

LDPE Applications

Low density polyethylene washers are valued for their flexibility, which makes them useful in applications that require a tight seal on geometrically unusual joints. Since it is more impact resistant than HDPE, LDPE is often employed in applications with frequent impacts, vibrations, and pressure fluctuations. LDPE is also water-resistant, so it is often used in tubing to convey liquids, such as water systems, drains, and fluid feeds.

LDPE washers are also resistant to corrosive chemicals, which makes them ideal for use in chemical processing, oil and gas, and marine applications.

HDPE Applications

High-density polyethylene washers are stronger than LDPE, but less flexible. They are particularly resistant to crushing and abrasion, which makes them valuable for use in many industrial and mechanical applications. HDPE washers are valuable for their tensile strength, and as such are often used to distribute pressure joints and to support fastening apparatuses. HDPE washers are also highly impact resistant, so they are useful for high-impact and high-pressure applications.

Benefits of Polyethylene Washers

Both LDPE and HDPE washers are affordable, easily formable, and simple to produce in large quantities. Depending on the needs of the application, each material offers its own unique benefits.

Benefits of LDPE Washers

- Superior flexibility

- High elasticity

- Toughness

- Tear-resistant

- Water-resistant

- High tensile strength

- Impact-resistant

Benefits of HDPE Washers

- High tensile strength

- Water-resistant

- Chemical-resistant

- Abrasion-resistant

- Tear-resistant

- Food-grade available

- Impact-resistant

Polyethylene Washers from New Process Fibre

Since 1927, New Process Fibre has been a preeminent provider of high-quality washers made from wide range of materials, including polyethylene, nylon, acetal, vulcanized rubber, and many more. In addition to our wide array of washers, we offer a variety of custom stamping and fabrication services for numerous industries.

As a one-stop shop, New Process Fibre provides non-metallic stamping services for every step of the manufacturing process, from custom design through production and final inspection. Our ISO 9001:2015 certified facility ensures exceptional products through the application of rigorous quality assurance standards.

For more information on our superior polyethylene washers, contact us today or request a quote.