At New Process Fibre Company, Inc. (NPF), we’ve offered a range of innovative, custom non-metallic stamping and fabrication services since 1927. We have the experience, in-house production and tooling capabilities, and extensive material inventory to meet our customers’ varied specifications and product requirements.

Nylon is a popular alternative to metal for creating stamped parts for machinery and other applications. The material is extremely versatile and durable, making it an ideal option for components in widespread industries. Our team works with multiple types of nylon, one of which is high-performance nylon MDS. Learn more about this long-lasting material, its applications, and how the experts at NPF can support your operations with high-quality nylon components.

What Is Nylon MDS?

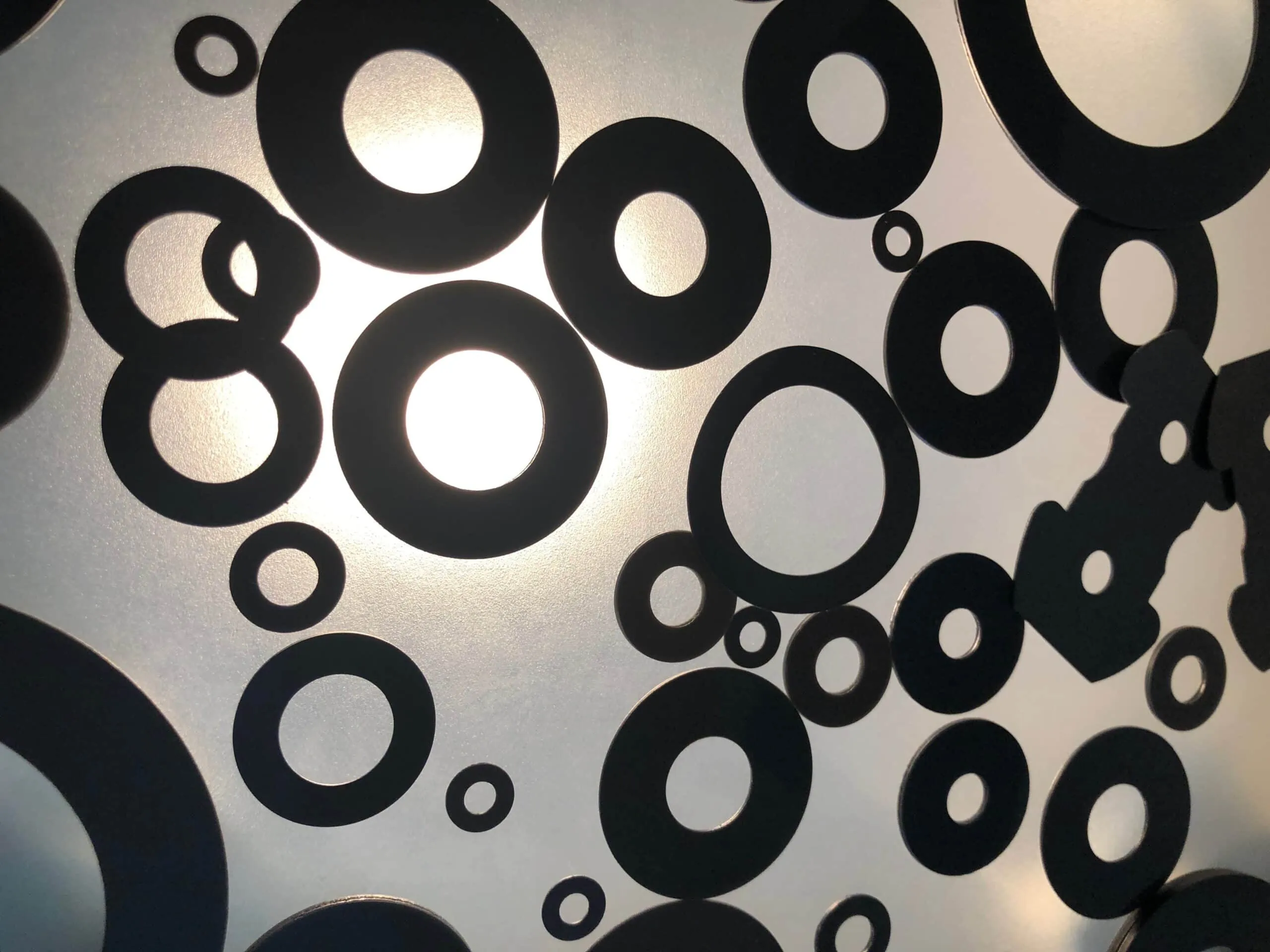

Using nylon 6 or nylon 6/6 as a base, nylon MDS material includes the addition of fine MDS particles. Adding MDS increases the nylon’s capability to bear larger loads and enhances its other properties, all without altering the well-known impact resistance of the base material. It surpasses nylon 6 and nylon 6/6 molecular weight. Nylon MDS holds up well under high mechanical stress, it is self-lubricating, and given its high durability, wear resistance, and overall toughness, it can also serve as a replacement for metal in machine parts like washers. NPF produces both nylon MDS 6 and nylon MDS 6/6 to fit your application’s unique needs.

What Are the Properties of Nylon MDS?

Building on the capabilities of the base nylon material, nylon MDS possesses a range of beneficial properties. MDS-filled nylon 6/6 and nylon 6 offer very high resistance to wear and decreased surface friction. This plays into the material’s high strength, durability, rigidity, and overall toughness. In addition to its high load-bearing capacity and enhanced dimensional stability, nylon MDS is also chemically resistant and an electrical insulator. It offers excellent lubricity, with a degree of self-lubrication comparable to PTFE. All of these properties equate to a long service life for any parts made from nylon MDS. Components of this material have the potential to outlast their metallic counterparts, meaning nylon MDS is also a cost-effective option for reduced production costs.

Applications of Nylon MDS

Diverse applications rely on nylon MDS for durable parts and products, particularly those requiring superior toughness to withstand environments involving high mechanical stress, pressures, friction, impacts, or chemicals and solvents. Due to its self-lubricating capabilities, this material can also fill in for grease fittings when such a component isn’t advisable for fear of contamination. Nylon MDS is highly versatile, making it applicable in the automotive, aerospace, military and defense, marine, construction, plumbing, oil and gas, healthcare, and pharmaceutical sectors, among others.

Nylon MDS is the ideal material construction for many non-metallic machinery parts, such as:

- Washers

- Gaskets

- Fasteners

- Bearings

- Bushings

- Gears

- Cams

- Sprockets

- Rollers

- Insulators

A number of products commonly use such nylon MDS components to function, including:

- Equipment for the pharmaceutical industry

- Food-processing applications

- Household appliances such as blenders and vacuum cleaners

- Automotive & marine parts

- Power tools

- Exercise equipment

- Farm and garden equipment

- Outdoor clothing

- And more…

Why Choose New Process Fibre for Your Nylon MDS Needs?

As a reliable material for long-term use, nylon MDS is an optimal alternative to other materials like metal or Teflon. While manufacturers have multiple options for non-metallic stamped parts, nylon MDS’ unique properties lend it great versatility, making it an effective material choice for a wide range of industries.

NPF is a leading expert in nylon MDS washers and other nylon products. Our nylons are made with virgin materials, ensuring the best quality products for our clients. Our well-equipped facility and decades of expertise in the nylon industry allow our team of professionals to offer high-quality, in-house manufacturing services for standard and custom non-metallic products that meet the varied needs of our clients.

NPF is here to assist you in finding the right nylon material for your specific application and budget. Contact us today to learn more about our material options and capabilities.