Since 1927, New Process Fibre Company, Inc. (NPF) has specialized in stamped non-metallic flat components that achieve tight tolerances and comply with industry quality assurance standards. Our family-owned company places a premium on quality, producing high-performance yet cost-effective parts for clients in diverse industries.

In addition to our in-house custom stamping and fabrication capabilities and our state-of-the-art tooling, we offer an extensive material selection and inventory. Our team produces many of our materials, including nylons, in our facility for optimal quality control. Learn more about one of our nylon options, nylon 6, and how it supports quality and performance in our non-metallic components.

What Is Nylon 6?

There are eight varieties of nylon, differentiated by the amount of carbon atoms present in each type’s dibasic and diamine acid monomers. Nylon 6, or polycaprolactam, is a type of semi-crystalline polyamide made from six carbon atoms. The material forms during caprolactam’s ring-opening polymerization and has a chemical formula of (C6H11NO)n.

Paul Schlack, a chemist from Germany, invented this nylon variety in 1939. Soon after, the fiber industry adopted nylon 6 for a wide range of applications that are still expanding today, over 80 years later. With high tensile strength and impact and abrasion resistance, nylon 6 is ideal for non-metallic stamping and tooling. For applications requiring even greater wear resistance, MDS-filled nylon 6, or nylon 6 fibers containing molybdenum disulfide, provides even greater physical properties.

How Is Nylon 6 Made?

The ring-opening polymerization process of nylon 6 begins when you heat caprolactam to 250° C and introduce roughly 4% water. Each H2O molecule donates a proton to caprolactam’s carbonyl group, resulting in a positively charged carbonyl carbon atom. This causes a chain reaction that breaks the amide bonds of caprolactam, opening its molecular rings and reforming them into a new six-carbon polymer backbone.

What Are the Properties of Nylon 6?

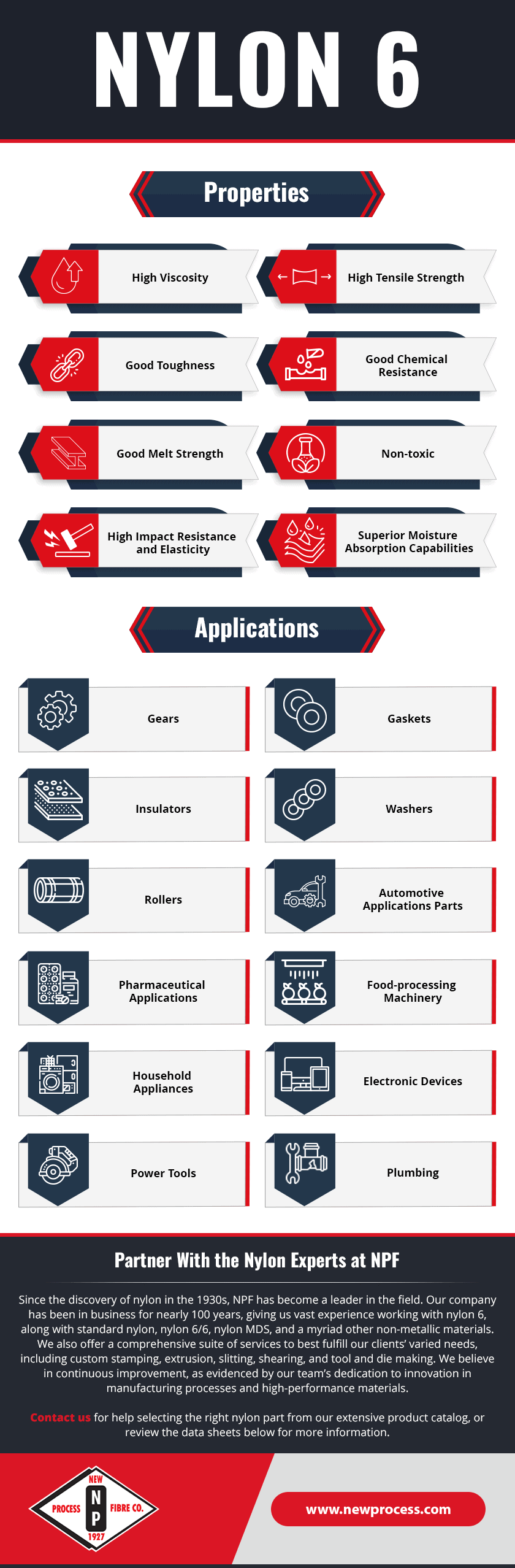

With high viscosity and tensile strength, as well as good toughness, chemical resistance, and melt strength, nylon 6 is ideal for non-metallic stamping purposes. It’s also non-toxic, giving it a broader range of applications in sectors from pharmaceuticals to food processing.

While nylon 6/6 is harder and has a slightly higher melt temperature, nylon 6 has greater impact resistance and elasticity, making it a preferred material in a wide array of industrial projects. For example, the automotive industry often uses nylon 6 washers for high-torque applications, as nylon 6/6 is more prone to cracking. Nylon 6 becomes increasingly brittle in colder temperatures, but it’s more impact resistant in wet environments than some other nylon alternatives, largely due to its superior moisture absorption capabilities.

When in doubt, NPF’s nylon experts can assist you in choosing the right material for your application.

Applications of Nylon 6

Given its numerous benefits, nylon 6 is a highly versatile material with widespread applications across industries. It’s common in industrial as well as consumer-grade products, such as:

- Gears

- Gaskets

- Insulators

- Washers

- Rollers

- Automotive applications parts

- Pharmaceutical applications

- Food-processing machinery

- Household appliances

- Electronic devices

- Power tools

- Outdoor clothing

- And much, much more…

Partner With the Nylon Experts at NPF

Since the discovery of nylon in the 1930s, NPF has become a leader in the field. Our company has been in business for nearly 100 years, giving us vast experience working with nylon 6, along with standard nylon, nylon 6/6, nylon MDS, and a myriad other non-metallic materials. We also offer a comprehensive suite of services to best fulfill our clients’ varied needs, including custom stamping, extrusion, slitting, shearing, and tool and die making. We believe in continuous improvement, as evidenced by our team’s dedication to innovation in manufacturing processes and high-performance materials.

NPF nylons are made with virgin materials to ensure we deliver products of the highest quality. However, as part of our commitment to green initiatives, our clients also have the option of using recycled materials whenever possible to lessen their carbon footprint. Salvageable plastics are either reused or sent to other manufacturers to include in new products, leading to zero waste.

Contact us for help selecting the right nylon part from our extensive product catalog, or review the data sheets below for more information.