For nearly a century, New Process Fibre has created high-quality, non-metallic products. Using state-of-the-art stamping and extrusion equipment and an extensive range of materials, we produce thermoplastic sheets, rolls, washers, gaskets, and more that adhere to even the most rigorous industry requirements. Our quality assurance standards include first article inspection, PPAP documentation, and REACH and RoHS compliance.

Learn more about the plastic sheet rolls we provide, including the applications and benefits of these products.

How Are Plastic Sheets Made?

Plastic sheets are flat, fairly stiff, continuous pieces of plastic material. While they can be thin, they are typically more substantial than a film. Since there are many polymers suitable for making plastic sheets, as well as highly diverse end-uses, the specific processes involved vary. However, in general, the chosen polymer and any desired additives are melted and then squeezed through a small slit for casting. This process is called extrusion.

The melted plastic fills the extrusion mold, where it remains until it cools into a solid sheet. This process creates plastic sheets in many thicknesses and dimensions. After they’re produced, they can be further cut and shaped if necessary, or used to create other components like washers. You can learn more about the extrusion processes we use and how they work on our Extrusion and Slitting Services page.

Types of Plastic Sheets and Plastic Rolls We Offer

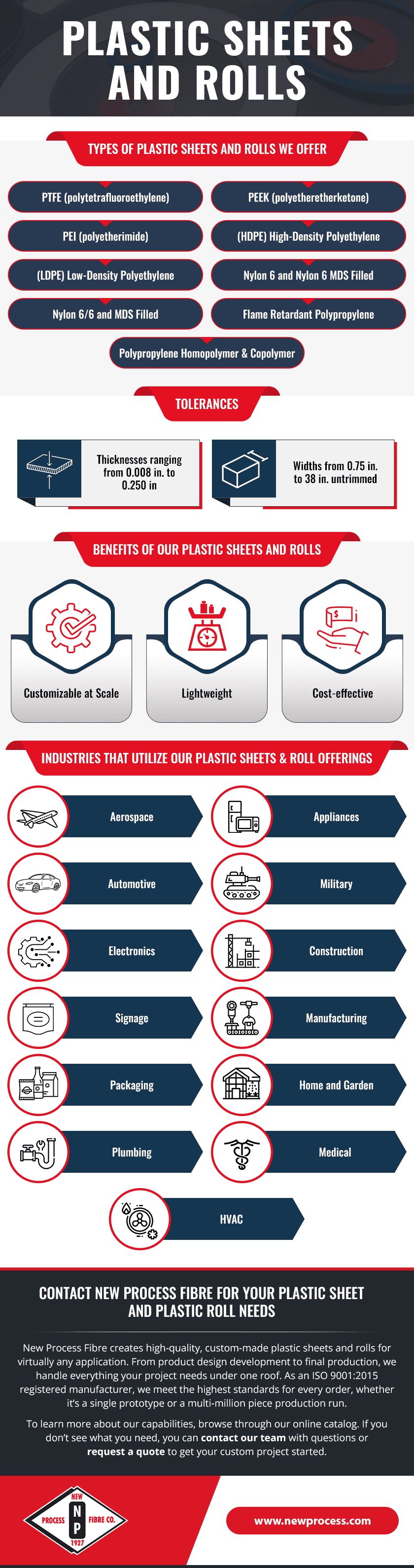

At New Process Fibre, we produce custom plastic sheets and plastic rolls using a number of materials:

- PTFE (polytetrafluoroethylene): Commonly referred to by its brand name, Teflon™, this material is characterized by its low coefficient of friction and high chemical resistance. It demonstrates excellent flexural strength, electrical resistance, thermal stability, and weather resistance. PTFE can be used in temperatures from -378 °F to 500 °F.

- PEEK (polyetheretherketone): As a high-performance engineering plastic, PEEK has a semi-crystalline structure and is resistant to chemicals, fatigue, creep, and heat. In addition, it has the highest tensile and flexural strength of any high-performance polymer. Due to these qualities, PEEK is a suitable metal alternative for many applications, since it remains strong and adaptable to harsh environmental conditions. PEEK can be used in continuous operating temperatures of up to 500 °F.

- PEI (polyetherimide): Also known by the brand name Ultem®, PEI is one of the few commercially available amorphous thermoplastics. It is flame- and chemical-resistant, strong, and has the highest dielectric strength of any high-performance thermoplastic. It can be used continuously in temperatures up to 338 °F.

Our plastic roll and sheet products include:

- Acetal Copolymer Sheets & Rolls

- Delrin® Homopolymer Sheets & Rolls

- (HDPE) High-Density Polyethylene Sheets & Rolls

- (LDPE) Low-Density Polyethylene Sheets & Rolls

- Nylon 6 and Nylon 6 MDS Filled Sheets & Rolls

- Nylon 6/6 and MDS Filled Sheets & Rolls

- Polypropylene Homopolymer and Copolymer and Flame Retardant Polypropylene Sheets & Rolls

Tolerances

Our skilled team can meet the requirements of virtually any plastic sheet roll application. In addition to creating products in custom lengths, we can produce thicknesses ranging from 0.008 in. to 0.250 in., and widths from 0.75 in. to 38 in. untrimmed. The tolerances we are able to achieve vary based on the material, so get in touch for information specific to your project’s needs.

Benefits of Our Plastic Sheets and Plastic Rolls

Plastic sheet rolls from New Process Fibre offer benefits for many industries and applications. Whether you need a product with extreme impact resistance, low water absorption, or another characteristic, we can develop a solution for you. The plastics we work with are also easily customizable according to your required size, shape, color, and finish. Our thermoplastic rolls are affordable in small quantities and come with special discounts for higher volumes.

Key benefits include:

- Customizable at scale: We can easily manipulate plastics into virtually any desired shape and size and offer a wide variety of colors and finishes, and we can do this at scale.

- Lightweight: Plastics are strong yet more lightweight than metals and glass. This makes them easy to handle and transport, and an excellent solution for weight-sensitive applications.

- Cost-effective: Plastic sheets and rolls are much more cost-effective to produce than alternative materials and typically require fewer secondary operations.

Industries that Utilize Our Plastic Sheets and Roll Offerings

Plastic sheets are used in a huge array of applications. Our products are cut to size, routed, and machined to meet specific industry needs. While the specific applications that our plastic sheets and rolls can be used in are virtually endless, here are some of the top industries that regularly use our materials:

- Aerospace: Since plastic sheets are incredibly lightweight, they are ideal for many aircraft interior components, like seating features and bulkheads.

- Appliances: Blenders and power tools use vulcanized fiber armatures or end laminations, while nylon washers are used in conjunction with armatures in applications where grease fittings cannot be used.

- Automotive: Plastic sheets are useful for many interior automotive components, as well as mass transit vehicle barriers.

- Military: Polycarbonate sheets and other strong plastics provide reliable impact resistance in armored vehicle glass and windshields.

- Electronics: Plastic sheets are commonly used as insulators or dust covers, preventing dirt from being drawn into electronic devices. They are also used in everything from computer screens and switches to fire alarm pull switches to other electronics that require non-conductive materials.

- Construction: Everything from skylights to greenhouses can be produced from plastic sheets, as well as numerous other applications, like templates for home kitchen countertops.

- Signage: Many types of plastic can be printed on or produced in a variety of colors and shapes, making them ideal for retail displays and signs.

- Manufacturing: Plastic is durable enough for use in conveying equipment, wear strips, and heavy machinery used to move products throughout manufacturing facilities.

- Packaging: Plastic sheets are used in packaging facility conveying equipment as well as in the packaging products themselves.

- Home and garden: Landscapers use thin sheets of green plastic under fencing to deter grass growth, reducing the need for weed killers and costly labor. Plastic sheets are also used to line ponds and vegetable garden beds.

- Plumbing: Materials such as Teflon™, Delrin®, and nylon are used inside faucets, while high-density washers are found in tubs. Low-density washers help connect water spouts to the wall, among many other uses.

- Medical: Plastic sheets are used to produce medical face shields, colonoscopy machine components, respirator washers, dental equipment, and many other components.

- HVAC: HVAC system compressors commonly use PTFE washers. In addition, high-density plastic washers connect units to buildings without unwanted vibrations and noise.

Contact New Process Fibre for Your Plastic Sheet and Plastic Roll Needs

New Process Fibre creates high-quality, custom-made plastic sheets and rolls for virtually any application. From product design development to final production, we handle everything your project needs under one roof. As an ISO 9001:2015 registered manufacturer, we meet the highest standards for every order, whether it’s a single prototype or a multi-million piece production run.

To learn more about our capabilities, browse through our online catalog. If you don’t see what you need, you can contact our team with questions or request a quote to get your custom project started.