This past summer, we had the pleasure of sitting down with engineering.com to talk about non-metal stamped parts production. We talked about a little bit of everything, ranging from non-metal stamp considerations, to custom tooling and production volumes for stamped parts produced in house. Check out the article below, or click here for the full edition.

A part of Everything, with New Process Fibre Company, Inc.

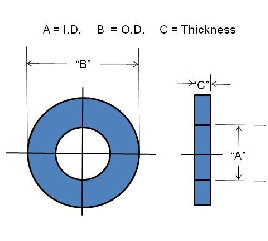

Stamped parts like washers – found in everything from recliners, to kitchen blenders, to cars, and much more – come in a variety of shapes, sizes and materials. With so many options, design engineers might pick the first material and form that meets their basic requirements, but this can lead to a sub-optimal design and problems down the line.

Engineers can work closely with washer manufacturers like New Process Fibre Company, Incorporated (NPF) to ensure they avoid any unexpected arrows to the heel of their design.

“A lot of engineers pick out the material, dimensions and tolerances they are looking for, but if they pick out a material and it doesn’t work, then they’re kind of stuck,” said Bill Rust, director of sales and marketing at NPF. “We’re here to help.”

Material Considerations for Stamped Parts

Engineers have plenty of good reasons to move away from metal materials and toward non-metallic ones such as thermoplastics, laminates and fibers for stamped parts.

Vulcanized fibre is a light and strong material often comprised of wood pulp, paper and rag material. With good impact and abrasion resistance, as well as high flammability ratings, vulcanized fibre can be used in automotive components or provide electrical insulation, among many applications.

Laminates are composed of various resins and are graded by the National Electrical Manufacturers Association (NEMA) for electrical, mechanical and chemical performance characteristics. They are often suitable for aerospace, automotive, electronics, industrial and petroleum applications.

Thermoplastics are composed of materials such as polyethylene copolymer and homopolymer, acetal copolymer, nylon 6, 6/6 or MDS—and the list goes on. Thermoplastics can be used for a wide range of consumer products and parts.

Good design engineers keep in mind tolerances for factors like heat, and capabilities like lubricant absorption and vibration dampening, when choosing a material.

For example, commodity thermoplastics are poor in electric motor applications, and are likely to melt on the armatures, while thermosets can crack or break in the wrong conditions, Rust said. This doesn’t mean plastics are ineffective or risky materials to use, but that design engineers need to be considerate of their performance requirements when selecting a material.

“Punching plastic is a little different than punching metal,” Rust explained. “Once you punch metal, that size isn’t going to change. Now plastic can pull moisture out of the air a little bit, and it can change the washer’s dimensions by a couple thousandths of an inch, especially if you leave the bag open overnight.”

Custom Design and Manufacturability for Stamped Parts

“We make parts to print here,” said Rust. “We need to know tolerances, dimensions and we need to know if this is a washer that they’re trying to retain to a bolt, where it will stay fixed in place without falling off.”

To ensure the tightest fits and tolerances, engineers can send in bolts to be built around and custom-order specific shapes and dimensions.

NPF’s standard tolerances achieve plus or minus ten-thousandths of an inch to even a thousandth on some materials.

Stamped parts can also be designed to meet specific absorption, compression and alignment requirements. For design engineers who aren’t quite sure what they are looking for, NPF can supply samples for inspection and testing.

“A lot of the stuff we do here are speciality washers and so instead of having a round ID or OD, they might have tabs on them or have a hex ID,” Rust said. “We have over 8000 washer dies on the floor. If we don’t have it, we build it and we make all of our own tooling here too.”

Custom Tooling and Production Volumes for Stamped Parts Produced In-House

Design engineers resort to custom tooling and die making when washers or other stamped parts require unconventional shapes and dimensions.

NPF has an in-house tool room with CAD/CAM and wire EDM capabilities, which allows them to create their own custom tooling.

“If you wanted a part that was in a special shape, like a rectangle, I would only quote a customer for the metal that it costs to build the tool and the die set, and it would be a one-time partial tooling charge,” Rust explained.

NPF holds ownership of the tool and maintains it for the lifetime of the part, which takes the worry and cost of having to inventory, maintain or store the tool off the customer’s shoulders. This practice extends to inventory and storage for excess production volumes to achieve lower costs on the quote.

“If a customer were to place an order for 100,000 parts and only needed 25,000, we would run the whole hundred,” Rust said. “We would keep the extra here on the shelf and release them as the customer needs them.

Working Together with New Process Fibre Company

NPF stamps non-metal materials including vulcanized fibre, acetal, nylon, Teflon, nylon MDS, high- and low-density polyethylene and other speciality materials for industries including consumer goods, aerospace, military, automotive, electronics, plumbing and many more.

With a large inventory and production equipment, NPF tackles production orders of all sizes, without the need for outsourcing, Rust explained.

“We extrude all our own materials,” Rust said. “We also slit our own materials and run the parts out on the press. Making and maintaining our own tooling, we do everything under one roof.”

NPF also manufactures custom discs, end laminations, gaskets, insulators, spacers and tags, as well as washers and parts.

Design engineers in need of assistance finding the right material for their application, can find help in the NPF Material Selection Guide, which includes material characteristics and highlights, common applications, and comparisons.