What Is Lexan Plastic?

Lexan is a brand name for polycarbonate, a plastic popular for its flexibility and durability. The brand name was created by General Electric (GE) in 1953, pioneering the development and production of the material in the U.S. Lexan’s unique chemical structure and fabrication process make it durable enough to be bulletproof but flexible enough to create delicate components. These versatile qualities have led manufacturers to utilize polycarbonate in a wide variety of modern products and parts.

Learn more about the benefits, limitations, and applications of Lexan to see if it’s the right material for your application.

Benefits of Lexan / Polycarbonate

Lexan is a strong thermoplastic that offers 30 times more impact strength than acrylic—another thermoplastic—and 250 times more impact strength than glass. Polycarbonate is ideal for applications where strength and protection are a priority. Here are some of its other benefits:

- Low rigidity (available in flexible grades)

- Withstands high temperatures (up to 240 °F) without deforming

- Resistant to harsh chemicals like acids and gasoline

- Can be drilled without the risk of cracking or shattering

- Cold formability

- Low flammability

- High strength-to-weight ratio

- Optical clarity similar to glass

- Does not degrade in the presence of pressure-sensitive chemicals

- Considered an eco-friendly material

Limitations of Lexan / Polycarbonate

With the degree of flexibility and strength Lexan offers, users should also be aware of the material’s inherent limitations:

- More prone to scratches than glass and other thermoplastics

- More expensive compared to glass and other thermoplastics

- UV rays may cause yellowing over time

- Easily dented

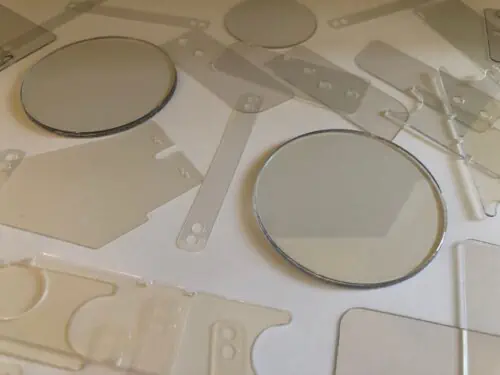

Examples of Lexan Products

If the goal is to create a highly protective material with less concern for aesthetics, Lexan is an excellent material.

Here are just some products that use Lexan:

- Electrical components

- Site glass in piping and machinery

- Tablets, computers, and phone cases

- Window well covers

- LED light diffusers and pipes

- Face visors and shields

- Machinery guards

- Automobile components like cluster panels

- Flashlight lenses

Applications of Lexan

Many industries rely on Lexan to create a variety of components and products. Here are some of the most popular examples:

- Aerospace/Automotive: Lexan makes durable, lightweight windshields for automobiles, aircraft, and trains. It’s also used to build isolation walls for bank counters and bullet-resistant automobile windows.

- Defense: The material is lightweight and has high tensile strength, making it ideal for building parts for military jet fighters and vehicles. Lexan is also used to make lightweight accessories for soldiers, lightening the loads they carry.

- Electronics Technology: Lexan is used to manufacture electronic components since it offers good insulation against electricity and resists corrosive chemicals and heat. Polycarbonate goes into screens for computers and televisions, as well as CDs and DVDs. The material is also commonly used for making video game controllers and cell phone cases.

- Eco-friendly Products: Lexan is highly recyclable, making it ideal for manufacturing eco-conscious products. These include food containers, water bottles, canteens and glasses. Lexan is a superior alternative to glass in these applications because it resists fractures while maintaining transparency.

Lexan vs. Acrylic

Acrylic’s trade name is Plexiglas, trademarked by Rohm and Hass. Its generic name is plexiglass, and other trade names include Acrylite and Lucite. Lexan and acrylic are similar thermoplastics commonly used as alternatives to glass, but they weigh half as much and are much more shatter-resistant than glass. Both materials are transparent, see-through plastics that have similar flexural strengths and are easy to clean.

Compared to Lexan, acrylic offers more light transmission, clarity, and shine. Additionally, acrylic is more resistant to scratches, UV light, and yellowing. However, protective coatings can help Lexan resist scratching. While Lexan can be formed in cold temperatures or bent without heating, acrylic can only be bent when heat is applied.

Lexan costs about 35% more than acrylic on average, but the extra cost can be justified by the unmatched impact resistance and durability Lexan offers.

Lexan/Polycarbonate and Other Non-Metallic Products From New Process Fibre

Lexan’s material properties make it a versatile plastic with extensive capabilities. Its impact resistance, durability, and lightweight properties are its main advantages over other plastics.

New Process Fibre Company is a top supplier of industrial non-metallic parts to manufacturers in various industries. We have years of fabrication experience processing thermoplastic materials like Lexan. Browse our product catalog, or contact us today to consult on your Lexan material needs. We can also advise you on appropriate materials for your non-metallic components.