Working with New Process Fibre: Tooling & Machinery

As an ISO 9001:2015 registered manufacturer, New Process Fibre offers superior quality tool and die manufacturing and nonmetallic stamping services custom-designed for specialized requirements. Learn more about our state-of-the-art tooling and machinery as well as the benefits of partnering with us for your tooling and nonmetallic stamping needs.

State-of-the-Art Tooling

With our advanced tooling and technology, we can efficiently perform all services, reducing production cycle times and adhering to stringent tolerances. We can accommodate our customers’ diverse design requirements using the following capabilities:

- 75 conventional and high-speed punch press machines

- More than 10,000 compound washer dies

- Vast material inventory

- Free maintenance of your tool for the full duration of your program, with only a partial tooling charge

- CAD/CAM

- Progressive and compound dies

- Custom die design and manufacturing

- Multi-cavity tools that save material costs and increase throughput

- Cost-effective and critical tolerance applications

- Wire EDM capabilities

- Automated wire EDM cutting can remove excess material without leaving damage or residual stress on the workpiece. It’s also ideally suited for hard, difficult-to-machine materials, reducing the need for secondary treatments. For the manufacturing sector, wire EDM often creates dies and molds, especially blanking punches and extrusion dies. The process can accommodate prototypes or large production runs of aerospace, automotive, and electronics components that have minimal residual stress.

Cutting-Edge Machinery

At New Process Fibre, we furnish our facilities with premium specialty equipment so that we can fulfill high-volume, high-speed orders of complex projects. Our two main types of equipment are Bruderer stamping press machines and Euromac CNC punching machines.

Bruderer Stamping Press Machines

Bruderer stamping press machines produce high precision, accuracy, and speed even when working with difficult materials or complicated designs for large volume runs. The machines feature responsive clutch and brake units that enable small changes and fine-tuning. Their first-punch accuracy means we can consistently ensure the quality and repeatability of the finished products. We keep our machinery well-calibrated and maintained to deliver optimal performance every time.

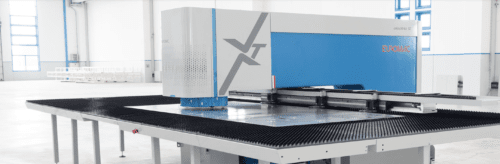

Euromac CNC Punching Machines

Benefits of Working with New Process Fibre

We continually improve our equipment to be the most up-to-date so that our customers receive the highest quality products on time. Some of these products can be punched without making a new tool, further reducing your production costs and turnaround times. Our machines are also dedicated to specific materials, such as sheet material, canvas, and G-10, ensuring the best quality for your nonmetallic products.

All hard tooling is developed in our in-house tool shop, which allows us to machine parts to tighter tolerances. Our niche method of developing tooling for customers means that you only pay a one-time tooling cost regardless of time.

Choose New Process Fibre for Your Tooling Needs

New Process Fibre is focused on building long-term relationships by going above and beyond project standards to add extra quality steps. With our broad inventory of materials, advanced machinery, in-house tooling capabilities, and strict quality controls, we provide the highest quality nonmetallic stamped parts for all our customers.

To learn more about our tooling, machinery, or other capabilities, contact us today.