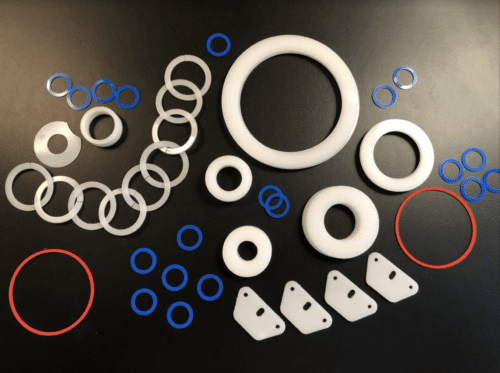

As a common alternative to metal washers, plastic washers for screws provide watertight seals, minimize vibrations, and offer unique benefits over their metal counterparts. These opaque or clear plastic washers are available in a wide range of material options to suit nearly every application. Here, we’ll discuss when to use plastic washers, including the common materials to consider when selecting a washer for your specific application.

Plastic Washers

For these reasons, plastic washers are an attractive, cost-effective option for many applications. Other benefits of plastic washers include:

- Vibration and shock resistance

- High-temperature resistance

- Weather resistance

- Water and moisture resistance

- Nonmagnetic

- Nonflammable

- Nontoxic

Plastic Washer Material

Plastic washers come in a variety of material options. The best one depends on the unique needs of your application. Here are the most common plastic washer materials:

- Nylon: Nylon is a highly versatile synthetic material that comes in several types and offers flexibility, abrasion resistance, chemical resistance, and machinability. This material is preferable for electrical and chemical applications due to its excellent absorption and insulation properties. Nylon washers are also a durable, lightweight alternative to metal washers in weight-sensitive applications.

- Teflon™: Also known as PTFE, Teflon™is known for its extremely low coefficient of friction and resistance to water and oil. Compared to other washer materials, Teflon™ offers exceptionally high chemical and thermal resistance properties. These low-friction washers are ideal for HVAC, automotive, and plumbing applications.

- Delrin®: Delrin® is a patented homopolymer with a stable crystalline structure that offers dimensional stability, stiffness, and durability in heavy-duty applications. The material also provides impact and temperature resistance from -50 °C to 90 °C, making Delrin® washers ideal for applications ranging from consumer goods to military equipment.

- Polyethylene (PE): We offer both low-density polyethylene (LDPE) and high-density polyethylene (HDPE) washers. The flexibility of LDPE washers is ideal for water-resistant applications in drains, water systems, and fluid feeds. HDPE washers are stronger and less flexible, so they are better suited to mechanical and industrial applications that value crush and abrasion resistance.

Plastic Washer Applications

- Power tools

- Furniture

- Fasteners

- Medical

- Farm and Garden

- Marine

- Aerospace and Military

- Government

- Sporting Goods / Fitness Equipment

- HVAC

- Plumbing

- Electronics

- Consumer and Kitchen Appliances

- Automotive

Plastic Washers From New Process Fibre

Plastic washers are a reliable alternative to metal washers for distributing fastener loads. Four of the most common materials include PE, Delrin®, Teflon™, and Nylon, each of which offers unique advantages.

To select the best plastic washers for your application, consult with an industry professional. Since 1927, New Process Fibre has been a leader in custom nonmetallic solutions. Contact us to learn more about our plastic washers for OEM equipment across diverse industries.