Plastic stamping offers an ideal plastic forming method for the affordable production of simple plastic goods in virtually any volume. When compared to machining, plastic stamping offers lower material costs, better repeatability, and faster production speeds when creating custom plastic components.

An essential process for many industries that create plastic and polymer parts, successful plastic stamping requires experienced personnel and state-of-the-art equipment to ensure success. This blog will explore the plastic stamping process, it’s benefits, and some of the available options it provides.

What are the Major Benefits of Plastic Stamping?

Plastic components are prized for their low weight, varying levels of hardness, and resistances to chemicals, heat, friction, and deterioration. Beyond this versatile range of physical properties, plastic stamping process offers a variety of other benefits, such as:

Accuracy

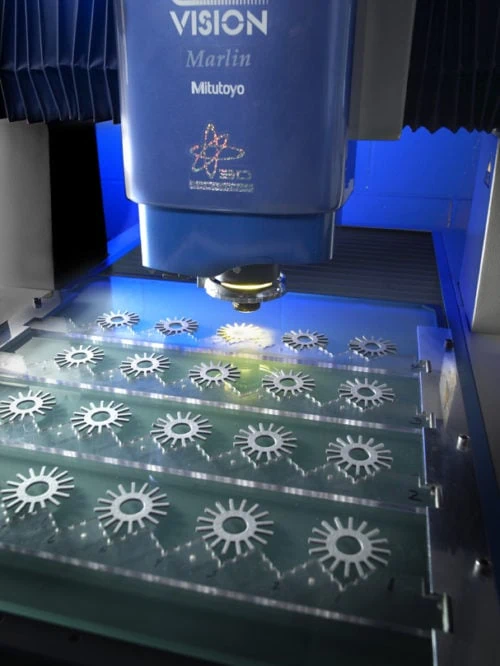

Plastic stamping machinery creates precisely manufactured components. Using durable dies to cut plastic parts from stock material, plastic stamping equipment offers excellent repeatability between parts within very tight tolerances. As long as the plastic stamping die stays in good condition, accurate and dimensionally consistent parts can be produced in virtually any volume.

Aesthetic Component Appearance

Plastic stamped components are blanked in a single operation, drastically lowering the likelihood of error. Components created via plastic stamping have crisp, uniform edges and an overall high level of uniformity that contribute to their aesthetic appeal. This single-operation process often minimizes or mitigates the need for secondary finishing processes.

Speed and Cost Efficiency

The speed at which identical components can be produced is often considered the ultimate benefit of plastic stamping. Some manufacturing facilities contain high-speed punches that are capable of cycling at speeds as fast as 400 strokes per minute while still producing highly precise components. Large-volume orders are extremely cost-effective, and the speed at which plastic stamping machines operate provides additional economies of scale on larger orders.

What are the Key Material Options fo Plastic Stamping?

Plastic stamping materials have variable characteristics in terms of appearance, elasticity, plasticity, strength, hardness, brittleness, and more. While a standard material is available to suit most applications, plastic materials can be formulated with specific physical characteristics in mind. Plastic materials also typically come in a variety of colors and can be easily color-matched when necessary. This makes it relatively straightforward to tailor the material to the part’s intended application.

Common plastic stamping materials include:

- Film

- Foam

- Laminate

- Phenolic compounds

- Plastic compounds

- Rubber compounds

- Vulcanized fiber (fish paper)

When deciding upon a material to use, the material’s brittleness plays a key role in the selection process. Hardness and brittleness tend to cohere, making it vital to select a material for the intended component that is hard enough to withstand the rigors of the intended use case without sacrificing formability.

Is Plastic Stamping Ideal and Affordable?

The plastic stamping process relies on a punch press and an associated set of stamping dies that punch an extruded plastic stock sheet or coil stock into the form specified by the design. As the stock material moves through the machine, pressure is applied to a single die or multiple dies in succession to cut the part from away from the stock. This method is ideal for the high-volume production of simple, flat items such as gaskets, seals, washers, laminations, and more.

Why Choose New Process Fibre for Plastic Stamping?

At New Process Fibre, our aim has always been to maintain the highest of quality standards in both our products and our business practices. Since our inception in 1927, we have continuously raised these qualities standards, allowing us to increasingly push the boundaries of what is possible regarding plastic stamping.

We are always seeking ways to improve our processes, technologies, and equipment, but one facet of our quality standards that we prize above all others is the people we hire to work behind the machinery. From figuring out more efficient ways to run a punching press to developing rapport with a new customer, our skilled employees are the best investment we could ever make, granting us the opportunity to lower costs, improve timeframes, and advance product quality for our valued customers.

Plastic stamping can be an affordable and ideal method when utilized to produce a variety of identical, quality components while saving customers time. For more information on how seriously we take quality standards, check out how we implement our quality assurance program. For any other questions, feel free to contact us today.