Polyethylene plastics are some of the most commonly used plastics on the market today. They are found in products you use every day, from water bottles to sandwich bags to garbage cans. Polyethylene plastics can be further broken down into High-Density Plastics (HDPE) or Low-Density Plastics (LDPE).

Polyethylene plastic is created through the polymerization of petroleum. Although HDPE and LDPE are both polyethylene plastics, they have visible differences. This is due to the differences in the manufacturing process. LDPE has an amorphous structure that isn’t organized, while HDPE has either a partially or completely crystalline structure, making it stronger and more durable.

High-Density vs. Low-Density Polyethylene

High-density polyethylene is a petroleum product. This polymer is melted into liquid form for easy molding and shaping. This allows manufacturers to create custom-shaped, durable containers. During manufacturing, HDPE experiences very little polymer branching, keeping the molecular structure very tight. The resulting material is strong and more rigid with the ability to retain its shape under pressure.

High-density polyethylene is a petroleum product. This polymer is melted into liquid form for easy molding and shaping. This allows manufacturers to create custom-shaped, durable containers. During manufacturing, HDPE experiences very little polymer branching, keeping the molecular structure very tight. The resulting material is strong and more rigid with the ability to retain its shape under pressure.

HDPE is ideal for projects that require custom printing or coloring. Since it’s both easy to manufacture and incredibly strong, it’s a preferred material for packaging. HDPE can also be made food-safe and it is capable of withstanding caustic chemicals.

LDPE is a lighter and more flexible plastic. LDPE polymer chains experience a considerable amount of branching and spreading. Since the chains are separated or scattered, the plastic has far less structure. The resulting plastic is lighter and more flexible. Its softness, however, means it is prone to damage.

Similarities Between HDPE vs. LDPE

There are numerous similarities between the two polyethylene plastics. Both plastics have a low material weight, are highly recyclable and have a high impact strength, and can be resistant to water vapor, weathering, and even chemicals. The tensile strength of both plastics ranges from 0.02 to 0.40 N/mm2 and are cost-effective to manufacture. Polyethylene is naturally inert, which provides both HDPE and LDPE with excellent mechanical and electrical properties.

Differences between HDPE & LDPE

The different production methods of the two substrates give them very distinct properties. These include:

- Physical Characteristics: HDPE is much sturdier than LDPE. LDPE has a lower melting point and the products are usually more transparent than HDPE products. LDPE is slightly abrasion-resistant but is the more fragile of the two plastics. HDPE is more rigid. This durability makes it more resistant to chemicals. It has a higher melting point, which means it can withstand greater temperatures. Unlike LDPE, it’s much less transparent. HDPE is fully abrasion-resistant.

- Recyclability: Both plastics can be recycled, but have different recycling requirements. LDPE is a recycling number 4 product and is more difficult to recycle due to its softness, increasing the risk of binding or clogging recycling machinery. HDPE is a recycling number 2 product and is easier to process through the recycling equipment.

- Production Methods: HDPE is manufactured by heating petroleum to an extreme temperature. This releases ethylene gas monomers, which combine to form the polymer chains. LDPE is created by compressing the monomer ethylene gas within a tubular reactor, or autoclave, to facilitate linking monomers, creating the polymer chain.

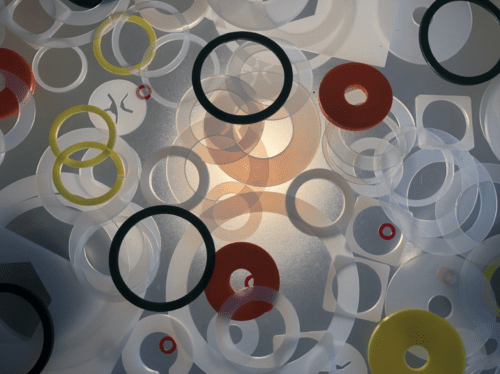

Applications of HDPE vs. LDPE

- Hydraulics and pneumatics

- Automotive

- Packaging

- Pipe and Piping

- Electrical

HDPE plastics are used in applications such as:

- Food processing

- Chemical and petroleum manufacturing

- Pharmaceutical processing

LDPE plastics are used for applications such as:

- Food processing

- Paper processing

- In the marine market

HDPE Solutions from New Process Fibre

While both HDPE and LDPE thermoplastic have their advantages, HDPE plastic creates more durable products for a wide range of applications. New Process Fibre specializes in complete HDPE stamping and die-cutting services. We are an ISO 9001:2015-certified manufacturer that provides custom thicknesses, widths, and colors to meet your project’s requirements.

Contact us for further information on our HDPE solutions.