F. Carl Porter founded New Process Fibre in 1927 based on an innovative idea: to process cotton paper into tough, resilient vulcanized fiber at far lower costs than were available at the time.

Throughout our history, we have provided custom parts for industries ranging from appliances and furniture to aerospace and the U.S. military. We are proud to continue serving clients with the same dedication and quality our name has come to represent over the past decades — with customers representing industries from every sector.

To read more about the industries we serve, click to expand the sections below.

Learn More

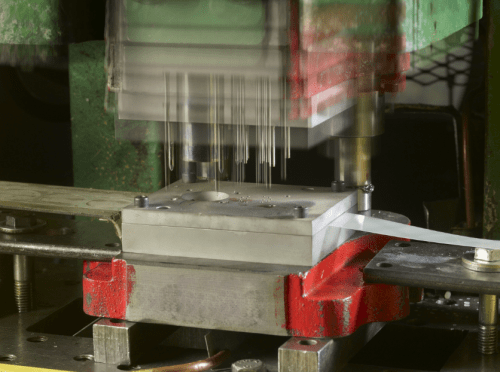

The outstanding quality of our work is made possible by our fleet of industry-leading equipment. We maintain 75 punch presses, including 14 high-speed presses, to fulfill orders of virtually any size or scope. Our facility contains over 8,000 washer dies, with our own die-sets manufactured entirely in-house. With this machinery, outsourcing is never necessary — creating the industry’s fastest turnaround times for low and high volume orders alike.