As part of our continued dedication to excellence in quality, New Process Fibre (NPF) has recently acquired and integrated a Keyence Instant Measurement (IM) 6225 Image Dimension Measurement System into our quality assurance processes.

An optical comparator, the IM 6225 is a cutting edge precision measuring system. It features highly precise optic components and a high-precision stage, newly developed by Keyence, which allow for a range of advanced capabilities.

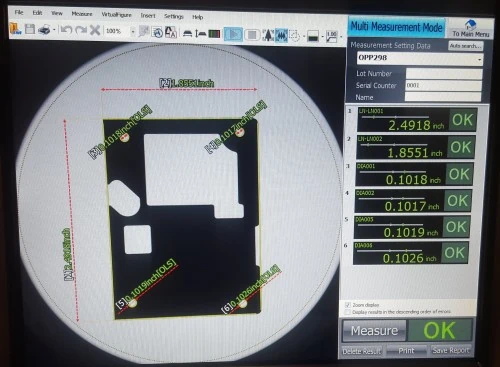

Keyence IM 6225

The unique features of the IM 6225 provide it with a number of important characteristics, making it a top-of-the-line piece of equipment.

Speed

A combination of advanced software and high quality precision optics, among other components, make the IM 6225 an exceedingly fast piece of vision-based inspection equipment. With automatic position and origin recognition, the IM 6225 can perform hundreds of individual measurements on a single part simultaneously.

Consistency

Fully automated, the IM 6225 is virtually unparalleled in its consistency and accuracy, even when used by different operators.

Among the automated functions that are performed with each measurement are:

- Focus adjustment — Aided by its specialty optics and large depth of field, the auto-focus function brings every measurement, regardless of varying part heights, into perfectly sharp focus.

- Light settings — When you get the perfect lighting conditions for a particular part, you can record them. From then on, whenever the IM 6225 detects that part, it uses the preset lighting settings.

- Edge detection — The IM 6225’s sub-pixel processing capabilities (100+ sub-pixels per pixel) automatically detect part edges for crisp, sharp images.

- Defect identification — Chips and burrs are automatically identified and highlighted by the IM 6225, easing and speeding the quality assurance process.

Ease of Use

Both the physical and graphical user interfaces of the IM 6225 are simple, intuitive, and extremely user-friendly. Measurements, guide lines, focus areas, and more can be defined, simply and easily, with just a few clicks of a mouse.

Flexibility

Flexibility

Every measurement result from each part scanned is automatically recorded by the IM 6225. This — combined with automatically populated histograms, provided trend graphs, and full inspection report generation, either printed directly from the IM 6225 or exported as a CSV file — give us the flexibility needed to manage your part inspection data effectively.

Operation

With virtually all of its functions automated through state of the art technology, operation of the IM 6225 is as simple as can be. An operator need only place a target part on the stage and press a single “Measure” button.

The IM 6225’s foolproof operation makes for a much faster quality assurance process. A faster process means that we can inspect more parts, which means your deliveries will have virtually nonexistent defect rates.

Keyence IM 6225 at NPF

Since integrating the IM 6225 into our quality assurance process, NPF has experienced improved productivity, reliability, and yield — our measurements are faster and more precise than they were previously.

Most importantly, the IM 6225 has allowed us to develop detailed measurement and quality histories for our parts. Important for establishing ideal process capability index (Cpk) values, and printing Certificates of Analysis and Certificates of Compliance, these part histories have been instrumental in developing visibility into processing trends — both for us and for our customers.

The Keyence IM 6225 has allowed for the consistent capture and retention of more accurate measurements, establishing thorough part histories, reducing floor traffic in our facility, and increasing production.

To have the quality assurance benefits of the Keyence IM 6225 Image Dimension Measurement System applied to your next project, consider working with New Process Fibre. Contact us today to get started.

Flexibility

Flexibility