Imagine a world of manufacturing with zero outsourcing, vast material options, and experts on every project — that’s exactly what you get when you work with New Process Fibre (NPF). After almost 90 years in business, our team is skilled at working quickly and cost-effectively to ensure that even the most unique custom projects move forward seamlessly.

Outsourcing unnecessarily wastes valuable time and resources. At NPF, we are dedicated to continuously updating and enhancing our in-house manufacturing capabilities to save our customers time and money. Combine these capabilities with a variety of diverse product and material choices, and a once-daunting project not only becomes feasible, but becomes achievable on an expedited timeline.

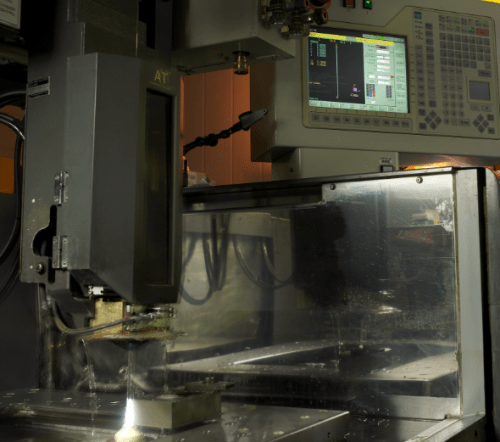

In-House Tooling

In-House Tooling

Working with both standard and custom components, our team completes all tooling in-house and assures top component performance with a thorough quality control check upon completion. In-house tooling provides a number of advantages over outsourcing:

- Short cycle time per part — as little as 2 weeks for a moderately complex part

- Tighter tolerances at no additional cost

- No downtime spent waiting for third party vendors

- Cost-competitive hard tooling

- Total control and monitoring start to finish

By slitting, shearing, and extruding in our own facility, we can supply a broad array of materials in specific dimensions to meet customer needs without involving a third party.

Diverse Material Inventory

Our three in-line sheet extruders can produce acetal copolymer, high and low density polyethylene, polypropylene homo and copolymer. The equipment also produces different types of nylon, such as nylon 6, nylon 6/6 and nylon MDS. Beyond the production of our in-line sheet extruders, we also manufacture components from our extensive inventory of materials including thermoplastics like Nylatron®, Teflon™ PTFE, Ultra High Molecular Weight and thermosets like G-10/FR-4 and Phenolic.

As one of the largest importers of vulcanized fibre in the United States, NPF fabricates countless vulcanized fibre washers and parts year round. Beyond these materials, we also offer a special selection that includes PEEK, Nomex®, Kapton® and Mylar.

Industry and Experience

Backed by our material offerings and manufacturing capabilities, we serve a wide range of industries including aerospace, automotive, construction, marine, and military. Businesses in the electrical, plumbing, furniture, and home and garden industries also benefit from our in-house work.

With nearly 90 years of experience, New Process Fibre is both reliable and flexible — a rare combination in our industry. Our ISO 9001:2008 and full PPAP capabilities assure our customers that their project is in good hands. With tight tolerances considered standard practice for our in-house hard tooling and careful shipping procedures to ensure quality deliveries, our production team ensures a quality product every time.

From the first point of contact, our team of experts will take care of your tooling and manufacturing needs with care and expertise. For more information on New Process Fibre’s capabilities, or to request a quote for a custom project, contact us today.

In-House Tooling

In-House Tooling